CENTINO uses advanced CAE software made by NEi Software.

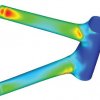

Their best-selling product NEi Fusion presents a new approach to structural Finite Element Analyses. It consists of a modern 3D modeler, pre- and post-processors and powerful solver based on a well-known NASTRAN technology.

NEi Fusion makes it possible to simulate and model behavior of actual structures and their elements using the most advanced finite element and CAD techniques.

CENTINO has the most advanced version of NEi Fusion software, including a nonlinear solver an essential tool for modeling parts and structures made of plastics!

Some other additional computational tools increase CENTINO capabilities.

Linear Statics.

Linear statics is one of the most common types of analyses needed by design engineers. After apply loads results can be displayed in a wide variety of formatsshowing stress, strain and deformation.

Nonlinear Static and Nonlinear Transient Response.

Allows material nonlinearity (material stress-strain data), contact (opening and closing of gaps and sliding), and large displacement and rotation (large defl ection) effects to be captured in analysis models. Additionally, transient and inertia effects can be included.

Assembly Modeling with Contact.

This tool allows designers to go beyond analyzing individual parts. Assemblies with different kinds of contact can be modeled including sliding, friction, and welded, allowing simulations to attain real world fidelity.

Automated Impact Analysis(AIA).

Ideal for performing projectile impactsand virtual drop tests. AIA takes a very complex, time-consuming simulation task. AIA requires a minimum of input data for the analysis — projectile velocity and acceleration. AIA determines the time steps, duration and complex contactinteraction between projectile and target.

Buckling.

Allows to examine structures for sudden failure modes caused by compressive forces.

Prestress.

Allows to induce an initial stress state on structures such as rotor blades or taut strings.

optimization using continuous or discrete variables. Model parameters and model dimensions can be made as optimization variables.

Linear Steady State Heat Transfer.

Using the principles of conduction and convection heat transfer, designs can be examine for equilibrium temperature distribution.

Nonlinear Steady State and Transient Heat Transfer.

Finds the steady-state solution to heat transfer models involving radiation, temperature dependent material properties, or other thermal boundary conditions such as convection or heat generation. Nonlinear thermal boundary conditions can vary through time. Thermal pulsations in exhaust systems and power fluctuations upon microchips can be modeled.

Frequency Response.

Determines the structural harmonic response based upon frequencydependent loads or enforced motions such as displacements, velocities, or accelerations.

Modal Analysis.

Determines the undamped natural mode shapes and frequencies of structures allowing to explore and resolve problems with noise and vibration.

Transient Response.

Used to determine the response of a structure through a period of time under the influence of constant or timedependent loads. Dynamic situations such as impulse loading can be modeled.

Composites.

Allows to analyze composite materials and laminated products.