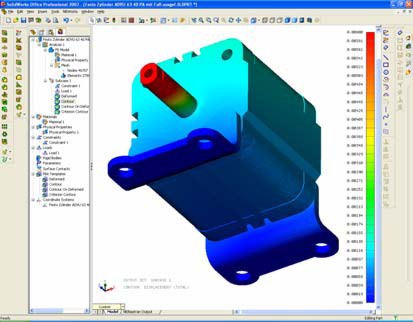

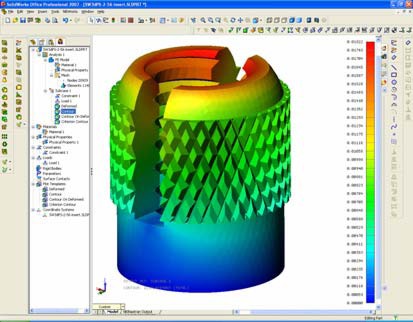

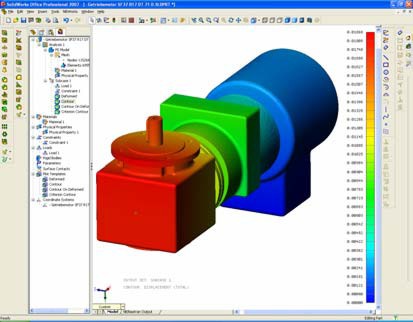

CENTINO does structural Finite Element Analyses of new and existing products, structures and other load bearing elements.

Finite Element Analyses provided by CENTINO support a design process and make it possible to determine the stresses and displacements of structures. Obtained results together with Computer Aided Engineering (CAE) help to optimize structures and their shapes, e.g. by reducing their weights.

We use NASTRAN for our calculations.

Material Orientation:

- Vector projection

- Curve tangent

- Rotated curve tangent

- Translated curve tangent

- Surface U and V directions

Properties:

- 1D beam (PBEAM) and bar (PBAR)

- 2D plate (PSHELL) and composite (PCOMP)

- 3D solid (PSOLID)

- Contact (BSCONP)

|

|

Surface Contact:

- Automatic surface contact generation

- General, welded, slide, rough, offset weld and RBE3 element contact types

- Static friction

Analysis Types:

- Linear statics

- Normal modes

- Linear buckling

- Nonlinear static

- Thermal stress

- Prestress static

- Composite

- Contact analysis in assemblies

- Linear steady state heat transfer

- Optimization

- Modal transient response

|

|

Composite Analysis:

- Various failure theories supported:

- Hill

- Hoffman

- Tsai-Wu

- Max. stress

- Max. strain

- NASA LARC02

Optimization Analysis:

- Design objectives to minimize, maximize or reach target values

- Parametrically update geometry dimensions

- Optimize weight, stress, material properties, temperature, natural frequency, plate and laminate properties thickness

|

|